Underground Mine Fans

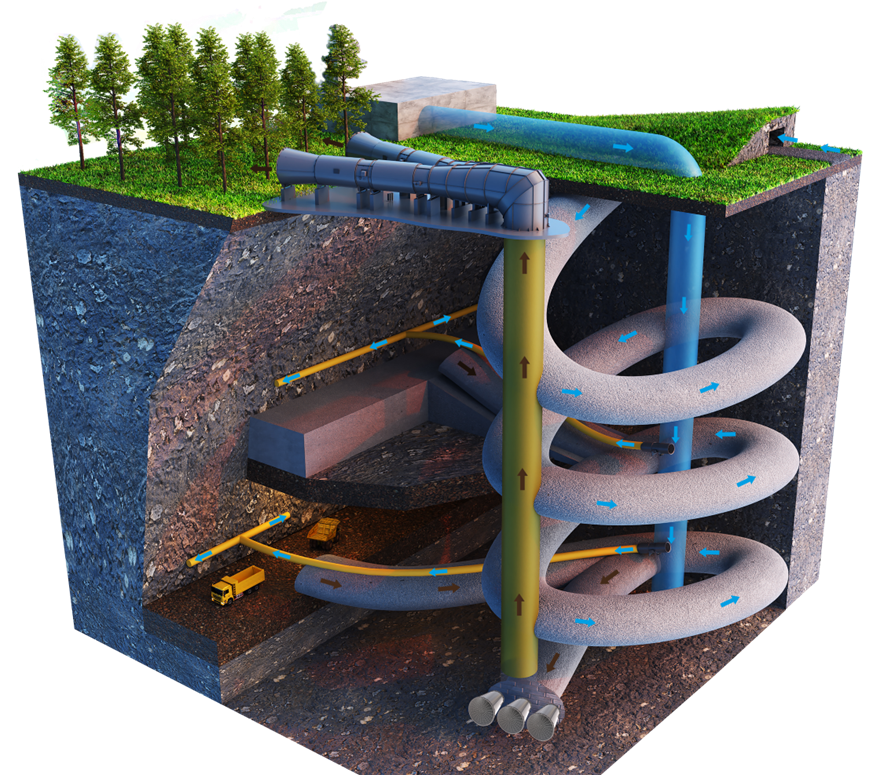

The implementation of underground ventilation in mining projects involves several aspects that begin with mine planning, considering geology, ore type, topography, number of workers, equipment used, and other factors. Based on this data, the ventilation system is dimensioned to ensure fresh air and worker safety.

For efficient ventilation, close collaboration between mine teams and ventilation engineers is crucial, working with all exploration information. Ventilation systems are designed to operate effectively even under the most critical scenarios.

Underground mine ventilation is subdivided into main ventilation (exhaust fans), booster ventilation, and secondary (auxiliary) ventilation.

Technical Information

|  |  |  |  |  | ||

Model | Diameter | Airflow (cfm) | Static Pressure (inH2O) | Rotation - rpm* | Maximum installed power (kW) | ||

Minimum | Maximum | Minimum | Maximum | ||||

M-FLOW 08 | 33in | 15.000 | 42.000 | 4,01 | 22,08 | 3600 | 3000 | 93 |

M-FLOW 10 | 39in | 21.000 | 63.500 | 4,01 | 26,10 | 3600 | 3000 | 149 |

M-FLOW 12 | 47in | 32.000 | 106.000 | 2,00 | 16,06 | 1800 | 1500 | 186 |

M-FLOW 14 | 55in | 55.000 | 201.000 | 2,00 | 22,08 | 1800 | 1500 | 373 |

M-FLOW 16 | 63in | 85.000 | 212.000 | 2,00 | 24,89 | 1800 | 1500 | 447 |

M-FLOW 18 | 71in | 106.000 | 297.000 | 2,00 | 27,70 | 1800 | 1500 | 522 |

M-FLOW 21 | 83in | 116.500 | 318.000 | 2,00 | 16,78 | 1200 | 1000 | Upon request |

M-FLOW 23 | 90in | 150.000 | 413.000 | 2,00 | 19,67 | 1200 | 1000 | Upon request |

The values shown are examples and for guidance only.

Contact us for more technical information by clicking hereMain Ventilation (Exhaust Fans)

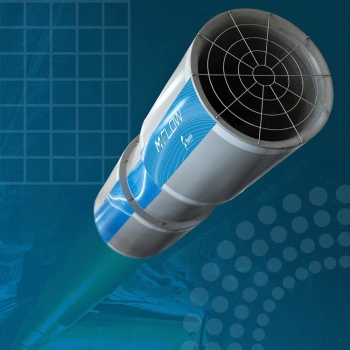

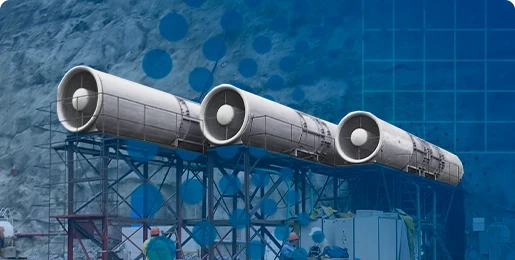

The main ventilation of a mine consists of exhaust-type fans installed in ventilation raises (vertical shafts) that connect the underground galleries to the surface, ensuring air renewal. They are divided into two types: intake raises, responsible for injecting clean air into the mine, and exhaust raises, which remove contaminated air. Main fans typically have diameters greater than 1.2 meters and power ratings above 150 HP, and can operate in systems with two or more units in parallel to guarantee the required airflow.

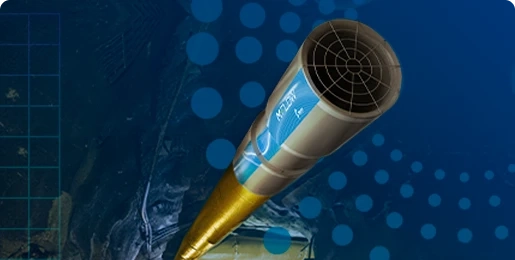

Secondary Underground Ventilation

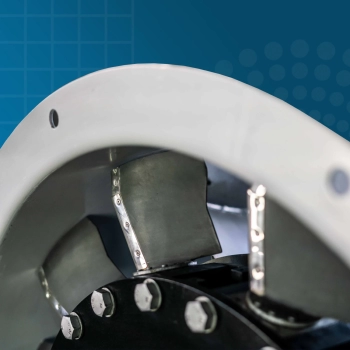

Secondary, or auxiliary, ventilation distributes air through the internal mine galleries. Using smaller fans, it is essential to deliver fresh air to the working faces through ducts that prevent mixing with contaminated air. The fans used must be axial, compact, robust, and capable of operating at high pressures. FanTR provides fans capable of reaching up to 6,000 Pa of static pressure, combined with low noise emission, high-durability blades, reinforced casings, and aerodynamic inlets. Optional features include automatic lubrication systems and vibration sensors.

Booster Fans

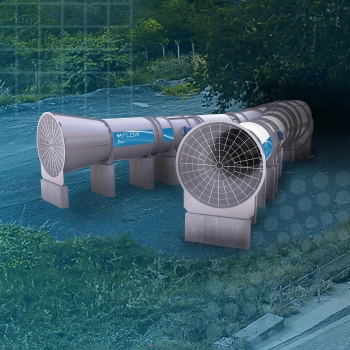

As a complement to the main system, booster fans are applied at strategic points of the primary ventilation circuit to maintain stable airflow in deeper or hard-to-reach areas. Usually installed in already excavated galleries, they help overcome pressure losses by providing additional pressure to the system. These fans supply the same airflow as the main system and can be configured in multiple-unit arrangements, integrating accessories such as noise attenuators and damping systems that ensure greater operational stability.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.