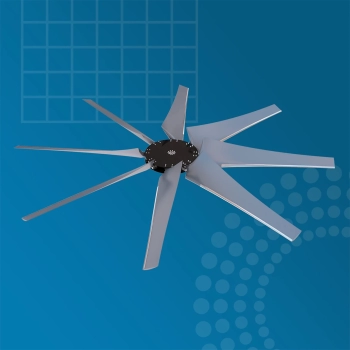

Composite Axial Fans

Technical Materials

Downloads - Composite Axial Fans

Manual valid for fans produced from 2018 onwards. For models prior to 2018, please contact FanTR through our

CONTACT CHANNEL: support@fantr.com. Phone: +55 11 4025 1670 - extension 2042

The Use of Composite Material in FanTR Fan Blades: Robustness, Durability and Efficiency

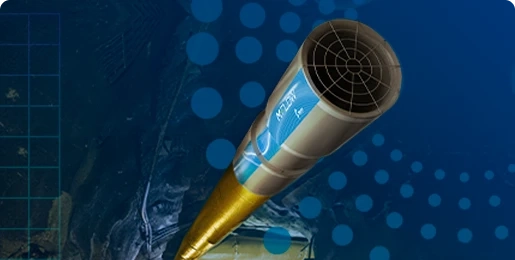

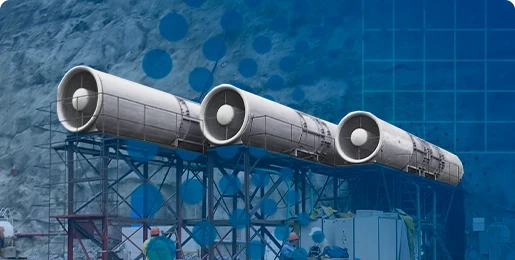

The use of composite materials in the manufacture of fan blades for cooling and underground ventilation systems is a significant technical differentiator. This material makes our equipment more robust, durable and efficient, guaranteeing superior performance.

What is a Composite Material?

A composite material is the combination of two or more different materials, which together have superior properties to their individual components.

These materials are made up of three main elements:

- Reinforcement: Responsible for giving the material rigidity and strength.

- Matrix: Keeps the fibers in the desired position and transmits the loads between them.

- Interface: Contact surface between the reinforcement and the matrix, essential for guaranteeing the structural integrity and resistance of the composite.

In FanTR, the most commonly used reinforcements are glass, aramid or carbon fibers, while the matrix is composed of thermosetting vinyl ester resin. The quality of the interface between these components is crucial to ensure structural performance and calculated resistance.

FanTR Manufacturing Process: Vacuum Infusion

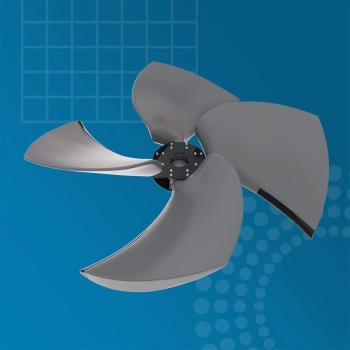

FanTR's composite blades are manufactured using the vacuum infusion process. This method allows for the precise positioning of layers of fabric, with different types of fibers and thicknesses, at specific angles. Just as in the aeronautical industry, our structural construction is optimized to direct the greatest resistance in the regions and directions most in demand.

Advantages of Composite Materials

In short, composite materials achieve excellent mechanical properties with the lowest possible weight, offering greater tensile strength and a higher modulus of elasticity than aluminum. In addition, these materials can be shaped into complex geometries, making it possible to manufacture aerodynamic profiles with large blade chords and high torsions, which guarantees maximum fan efficiency and performance.

Corrosion Protection

For applications in environments subject to corrosion, we use a chemical barrier made up of a vinyl ester matrix and gel coat. This combination gives the material a much higher resistance than aluminum and stainless steel, allowing our fans to operate safely in environments with a high concentration of chlorides, fluorides and other corrosive components.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.