M-Flow Main Fans

Technical Materials

Downloads - M-Flow Main Fans

Manual valid for fans produced from 2018 onwards. For models prior to 2018, please contact FanTR through our

CONTACT CHANNEL: support@fantr.com. Phone: +55 11 4025 1670 - extension 2042

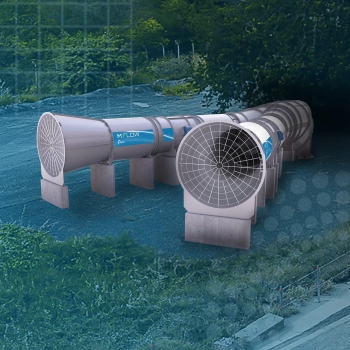

The main underground ventilation system is crucial to safety and efficiency in mining operations, being responsible for removing contaminated air from the main galleries and ensuring the entry of fresh air. The fans used for this application are predominantly exhaust fans, designed to pull stale and polluted air from inside the mine, creating a flow that allows clean air to enter through other accesses.

Characteristics and Technical Considerations

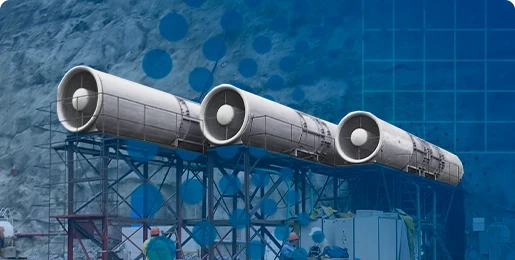

High Flow and Pressure

Exhaust fans used in primary underground ventilation need to operate at high flow rates and often under high pressure conditions. FanTR has developed axial exhaust fans capable of reaching pressures that were previously only possible with centrifugal fans. This innovation allows the use of axial fans that are more economical, efficient and easy to maintain, without compromising the performance required for underground environments.

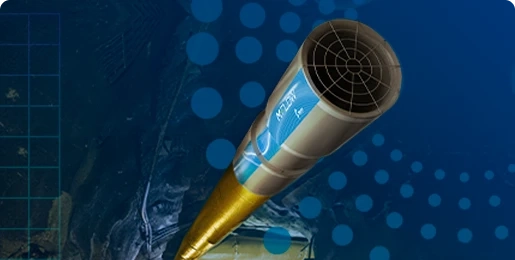

Erosion and Corrosion Resistance

The underground environment of a mine is highly corrosive and erosive due to the contaminated air, which can contain water, ore debris and rock particles. The propulsion assembly of the exhaust fans - rotor, blades and spinner - must be made of materials resistant to these extreme conditions.

FanTR's research and development center has created an exclusive line of rotors for axial exhaust fans that offer unparalleled resistance to erosion and corrosion, surpassing even rotors made of stainless steel. This ensures greater durability and less need for maintenance, even in challenging environments.

Adapting to Topography and Mine Operation

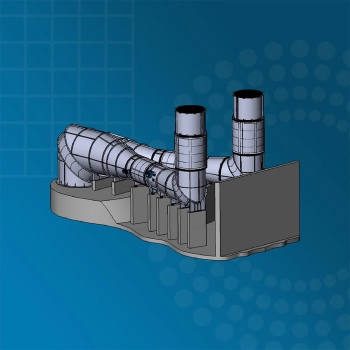

The topography of the site and the operation of the mine are determining factors in the sizing and installation of the main ventilation system. Often, a system combining several hoods in parallel is required to meet the specific demands of the point of operation. This configuration must be carefully adapted to the local topography and the mine's operational needs.

FanTR Integrated Solutions

FanTR offers complete, integrated solutions for main underground ventilation systems, working in partnership with the mining company's engineering to ensure that all operational parameters are met. Our projects include:

Drive panels: Control and automation systems for efficient exhaust fan operation.

Measurement system: continuous monitoring of performance and environmental conditions.

Aerodynamic design: cones, curves, bifurcations and other components designed to optimize air flow.

Dampers and noise attenuators: devices for flow control and noise reduction, essential for worker comfort and safety.

Vibration absorption system: technologies that minimize vibrations, increasing the useful life of the equipment.

With this personalized approach, FanTR stands out as a benchmark in ventilation solutions for mining, ensuring that your underground operations are safe, sustainable and economically viable.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.