Tunnel Fans

Underground Ventilation:

Underground ventilation aims to promote air flow in underground environments such as mines and tunnels. This air flow performs the extraction of hazardous gases and supports the temperature control. The hazardous gases result from the operation of combustion equipment, material from detonations, gases coming from the soil/rock, etc.

Tunnel ventilation: Tunnel ventilation is most commonly used in road tunnels, but it can also be used in railroad tunnels, cable tunnels, subways, hydroelectric plants, and

others.

There are two types of ventilation for underground tunnels: ventilation required for tunnel construction (temporary) and ventilation for tunnel operation (permanent). For the two applications mentioned, axial fans, also known as industrial axial fans, are mainly used.

Tunnel construction (temporary ventilation): at the construction stage, the most common ventilation method is the dead-end openings type, when clean air is injected into the tunnel through ducts, and contaminated air is expelled through the tunnel gallery itself. The main function of ventilation for tunnels is to provide conditions for workers to perform the work within legal, health, and comfort parameters. At this stage any type of tunnel should be ventilated, so we can add to the above list examples such as: gas pipelines, sewer tunnels, etc. In these cases, FanTR, in addition to the industrial axial fan, can supply a complete turn-key system also including ducts, fan mounting bases and drives.

Ventilation for tunnel operation (definitive ventilation): definitive tunnel ventilation is primarily required in places where people pass during tunnel

operation. The two most common applications are road tunnels and subways. The objective is to dilute the gases coming from the means of transport such as cars, trucks, buses, trains, among others, and to provide comfort for tunnel operators and users.

Additionally, the dimensioning of the fans for this application has a safety character, which is to guarantee clean air for the evacuation of people in case

of a fire (resulting from possible accidents). For this application, axial fans (industrial axial fans) are always used, which need to operate under a

temperature of 400ºC for 2 hours. FanTR has a complete line to meet this application.

Ventilation in underground mines

Often ore bodies are located deep underground. In order to achieve the best production rates and the best quality ore, it is very common to create completely underground mines. One advantage of this type of mining is that it does not alter the landscape and is less impactful on the environment. Because they are completely underground, fans for underground mines are essential to enable workers to perform their activities within legal, health, and comfort parameters.

Ventilation for underground mines is divided into 2 major groups:

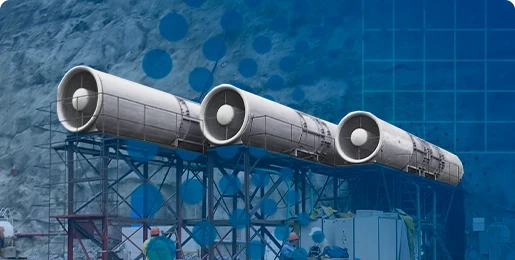

Main ventilation: responsible for providing clean outside air to the main mine galleries.

The fans to promote this type of ventilation are usually exhausters, meaning that they pull the contaminated air from inside the mine, causing clean air to enter through the other access points. For this reason, the sizing of this type of fan must follow specific criteria:

Point of Operation: these are high flow and often high-pressure fans. With the latest technology, FanTR can now manufacture axial fans capable of reaching

pressures that previously could only be reached by centrifugal fans, with the advantage of being more economic, efficient and easier to maintain.

Resistance: the propeller assembly (rotor, blades, and spinner) must be designed with materials resistant to high levels of erosion and corrosion from contaminated air coming from inside the mine. This contamination can include water, ore and rock debris, among other substances. FanTR's research and development center has created an exclusive line of rotors with unmatched resistance to erosion and corrosion. These rotors are superior to those made of stainless steel, for example. With our solution, we guarantee the longest durability and lowest maintenance on the market.

Suitability to the site topography and mine operation system: often, to meet the specified operation point, it is necessary to group more than one fan in

parallel. Therefore, it is necessary to design a main ventilation system, which in addition to meeting the operating point, must be suitable to the topography and site conditions, as well as to the mine control needs.

In these cases, FanTR is able to design and manufacture the system in an integrated way with the parameters mentioned above, together with the mining company's engineering.

This type of project/system may include: drive panels, measurement system, aerodynamic design of the cones, curves and bifurcations, dampers, noise

attenuators and vibration absorption system, besides other needs that may be requested by the mine.

Secondary ventilation: Responsible for capturing the clean air from the galleries coming from the main ventilation and directing it to the work fronts. In this system, the secondary ventilation works in the dead-end openings, meaning that the fan is installed on the mine's roof and connected to ducts that carry clean air to the excavation fronts. The dirty air is then expelled from the galleries through the work gallery to the main galleries and consequently "sucked" by the main ventilation.

In this case, fans for underground mines must be axial fans and capable of operating at high pressures. In addition, they must be as compact as possible

and extremely robust. For this application FanTR has mining equipment that can reach up to 6,000 Pa of pressure, with low noise emission, blades made of

composite material for high durability and a reinforced external casing to withstand impacts from trucks and machines, for example.

As an option, automatic lubrication system, bluetooth vibration sensors, built-in aerodynamic inlet nozzle, and other accessories can be added to the mining equipment so that it can operate as long as possible without operator intervention.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.