Booster Fans for Underground Mining

M-Flow

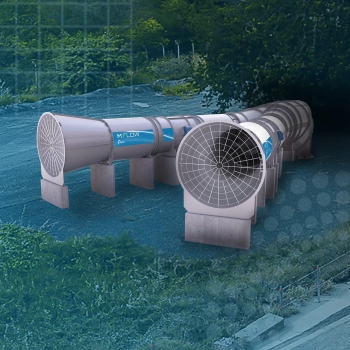

M-Flow Booster fans are large-scale units installed in the main ventilation circuit (intake or exhaust), designed to overcome the system’s static pressure increase.

Typically positioned in previously mined galleries, these fans provide positive static pressure, helping to maintain proper airflow and ensuring stability and efficiency in underground ventilation.

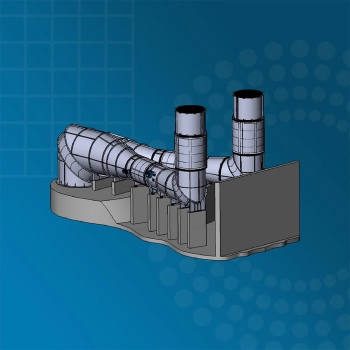

Installation can be carried out with one, two, or more fans in parallel, in galleries without vehicle traffic, where a bulkhead wall is built to direct the airflow exclusively through the fans.

Due to this type of setup, Booster fans require accessory components such as noise attenuators, vibration dampers, and connection rings, which ensure efficient, stable, and quiet operation.

It is essential that the Booster ventilation system airflow is aligned with the main ventilation system, ensuring proper airflow equalization and avoiding recirculation issues.

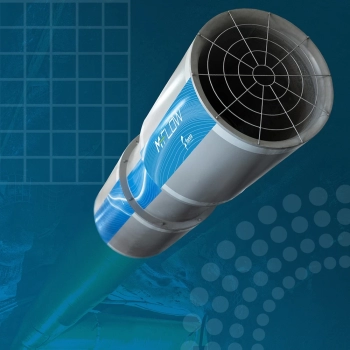

Request ContactThe new generation of the M-Flow line provides greater reliability and performance, with enhanced robustness and versatility to operate at high pressures and large flow rates.

Upgrades include reinforced structural plates, blade edges with three-times higher resistance, and optimized rotors for greater operational stability.

The improved cooling system extends motor life, while the new flange mounting (up to 1400 mm) allows the use of higher-power motors.

Specific versions are also available for operations above 1500 meters altitude, maintaining the same performance in any geographic condition.

Equipped with the WEGScan Bluetooth monitoring system, M-Flow fans enable predictive diagnostics, automatic alerts, and integrated battery recharging, elevating the standard of reliability.

Combining strength, efficiency, and flexibility, M-Flow Booster fans are ideal for reinforcing the main ventilation system, optimizing airflow circulation, and enhancing underground safety.

|  |  |  |  |  | ||

Model | Diameter | Airflow (cfm) | Static Pressure (inH2O) | Rotation - rpm* | Maximum installed power (kW) | ||

Minimum | Maximum | Minimum | Maximum | ||||

M-FLOW 12 | 47in | 32.000 | 106.000 | 2,00 | 16,06 | 1800 | 1500 | 186 |

M-FLOW 14 | 55in | 55.000 | 201.000 | 2,00 | 22,08 | 1800 | 1500 | 373 |

M-FLOW 16 | 63in | 85.000 | 212.000 | 2,00 | 24,89 | 1800 | 1500 | 447 |

M-FLOW 18 | 71in | 106.000 | 297.000 | 2,00 | 27,70 | 1800 | 1500 | 522 |

M-FLOW 21 | 83in | 116.500 | 318.000 | 2,00 | 16,78 | 1200 | 1000 | Upon request |

The values shown are examples and for guidance only.

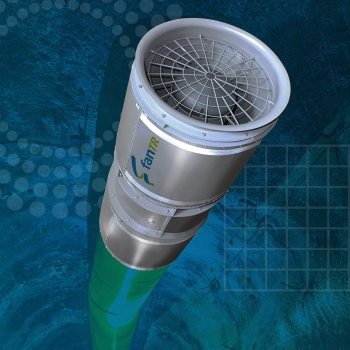

Contact us for more technical information by clicking hereSilent Attenuator

The model offers low noise levels due to the density and composition of the materials.

Increased Plate Thickness

Provides greater stability and higher impact resistance.

Motor Shroud

Motor shroud design makes the fan more aerodynamic.

Aerodynamic Stators

Stator design with aerodynamic profile.

Automatic Lubrication

Reduces maintenance needs and extends fan lifespan.

New Rotor Assembly

Greater precision in blade-to-housing clearance, with increased robustness.

Motor Cooling

Enhanced motor cooling system.

Lifting System

Simplified lifting system.

Monitoring System

Bluetooth monitoring with longer durability and modular battery replacement system.

Modified Spinner

Redesigned spinner for improved aerodynamic performance.

Reinforced Protection Screens

Protection screen redesigned for greater strength.

Leading Edge

Leading edge with 3x higher strength.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.