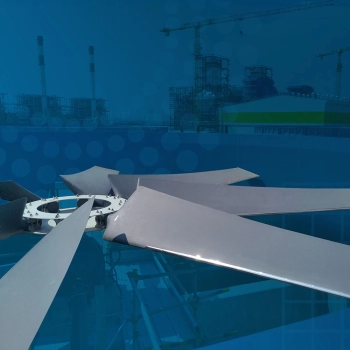

Fans for Cooling Towers, Air Coolers and Air-Cooled Condensers

Our cooling ventilation solutions are designed to meet the needs of industries that deal with high heat emissions. FanTR manufactures fans for cooling towers, air coolers, and air-cooled condensers, widely used in sectors such as refineries, petrochemicals, food processing, pulp and paper, aluminum, oil & gas, power generation (thermoelectric plants), steel, and metallurgy.

We produce industrial axial fans in composite material, always customized to meet each client’s specifications and requirements.

Technical Information

|  |  |  |  |  | |

| Diameter | Flow Rate | Application | No. of Blades | Feature | Leading Edge | |

SLSF | 63–156in. | 7–180 m³/s | AC | Tower | 3–5 | Ultra Low Noise | Polyurethane (PU) |

CR | 6–36ft. | 9–1.400 m³/s | AC | ACC | Tower | 4–12 | Wide Diameter Range | 316 Stainless Steel |

NCR | 14–42ft. | 50–1.900 m³/s | AC | ACC | Tower | 5–11 | High Efficiency | 316 Stainless Steel |

X-Flow | 32–42ft. | 50–1.900 m³/s | AC | ACC | Tower | 5–10 | Ultra High Efficiency | 316 Stainless Steel |

TEP | 12–36ft. | 35–1.400 m³/s | ACC | Tower | 5–11 | High Efficiency | 316 Stainless Steel |

STEP | 24–38ft. | 140–1.600 m³/s | ACC | Tower | 5–10 | Low Noise | 316 Stainless Steel |

FLN | até 20ft. | tbd | AC | ACC | Tower | 5–11 | Low Noise | 316 Stainless Steel |

HA line | 10–18ft. | 26–350 m³/s | Tower | 4–11 | High Corrosion Resistance | 316 Stainless Steel, |

The values shown are examples and for guidance only.

Contact us for more technical information by clicking hereFans with Composite Material Blades

FanTR’s industrial axial fans with composite material blades deliver greater strength and efficiency. As a specialist in composite manufacturing, FanTR develops unique designs and aerodynamic profiles with large chords and high twists, ensuring superior fan performance.

Standard Fans: CR, NCR, TEP, and X-Flow

CR: Entry-level model, with diameters up to 36 feet (11 meters). Replaces aluminum fans in cooling towers and air coolers, providing reduced operating costs and higher efficiency.

NCR: Evolution of the CR model, and the flagship product in our portfolio. Featuring a more modern and efficient design, it reaches up to 42 feet (12.8 meters) in diameter. Ideal for applications requiring fans larger than 14 feet (4.3 meters) in diameter.

TEP: Recommended for applications requiring lower speeds or fewer blades while maintaining high efficiency.

X-Flow: FanTR’s latest launch, designed to replace the NCR with a new aerodynamic profile. It provides greater lift per area and incorporates the aeroelastic load concept. Initially available in sizes from 32 to 46 feet (9.75 m to 14.02 m).

Low Noise Emission Fans: SLSF and STEP

SLSF: Axial fan with extremely low noise emission, available up to 13 feet (4 meters) in diameter. Ideal for coolers, condensers, and cooling towers in hospitals, urban areas, and other environments requiring silent operation.

STEP: Model with wider-chord blades, reaching up to 38 feet (11.6 meters) in diameter. Designed for low-speed applications, it is the ideal choice for cooling towers and air-cooled condensers.

Special Axial Fans: FLN and HA

FLN: Developed for low-noise applications as a replacement for CR fans. It applies noise-canceling technology through vortex generation at the trailing edge.

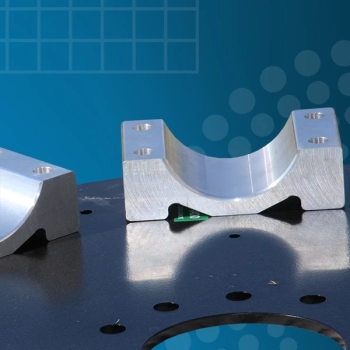

HA: Based on CR and TEP models, with a reinforced hub and fastening kit adapted for highly corrosive environments. These fans are especially used in zinc processing plants and environments with high concentrations of chlorides and fluorides in tower water.

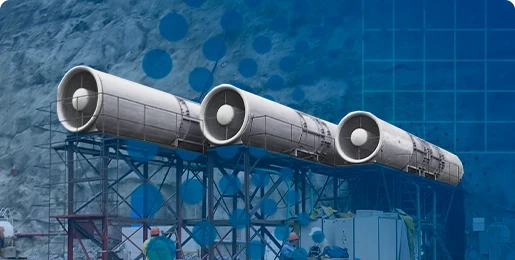

G-Flow System for Air Coolers

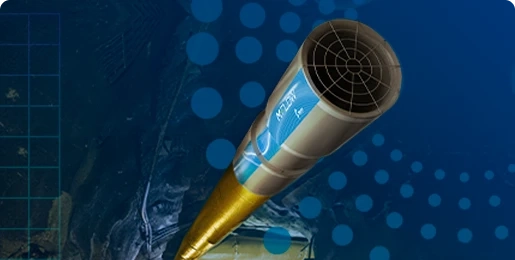

The G-Flow system developed by FanTR represents an advanced and highly efficient solution to replace the traditional pulley and belt drive system commonly used in air coolers. While pulley and belt systems may have a lower initial cost, they are known for requiring frequent maintenance, resulting in constant equipment downtime.

FanTR went further in innovation by developing a direct drive system that uses gear motors, providing greater robustness and reliability to the equipment. With G-Flow, maintenance and intervention rates are virtually eliminated, ensuring continuous equipment operation and offering greater predictability in predictive maintenance.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.