In Vazante, Minas Gerais, Nexa Resources faced a major challenge: ensuring efficient ventilation at the Sucuri 3 shaft without exceeding noise limits in the mine’s external area. The operation needed to be continuous, safe, and compliant with acoustic standards.

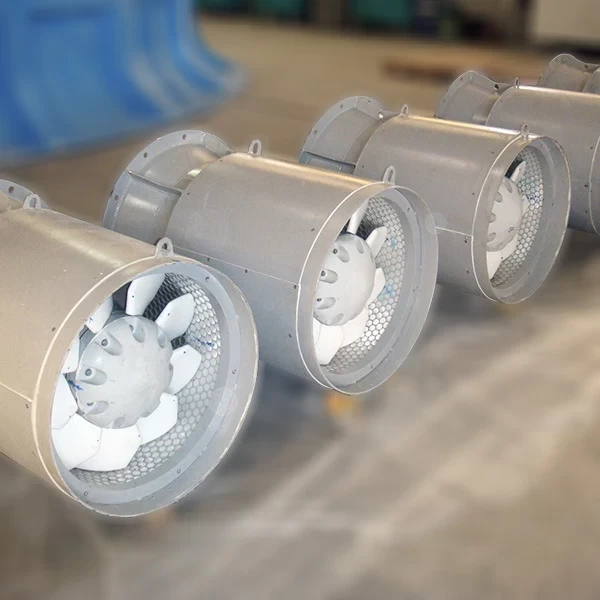

That’s when FanTR took on the project. Three fans were installed inside the mine, each with a 1,800 mm diameter, 700 HP power, and a nominal airflow of 89.5 m³/s. Together, they formed the core of the ventilation system.

The shaft’s proximity to the mine boundary added an extra requirement: controlling sound impact. To address this, FanTR designed and manufactured a custom acoustic attenuator, capable of reducing noise propagation without compromising fan performance.

Measurements strictly followed AMCA 210 standards. The rotation was calibrated at 1620 rpm, achieving the total design airflow of 269 m³/s. The system kept noise levels within the established limit: ≤ 40 dBA at the boundary.

The result was a system that not only met technical requirements but also showcased the integration of ventilation engineering and acoustic control. A project that strengthened the partnership between Nexa and FanTR in the pursuit of safe, efficient, and sustainable solutions.

What do you think about the implementation of this FanTR project?