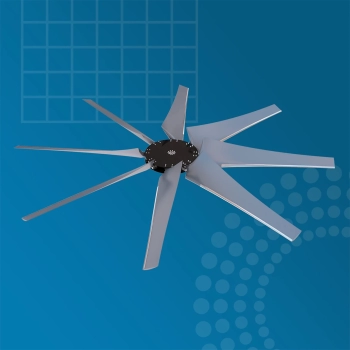

G-Flow SYSTEM

The G-Flow system, or Gear Flow, was developed as a superior solution to replace the traditional pulley and belt transmission system widely used in air coolers. Although the pulley and belt system offers a lower initial cost, it entails high maintenance requirements over time, resulting in frequent equipment downtime.

To address this issue, FanTR created G-Flow, a direct drive system with unique advantages focused on increasing equipment reliability. G-Flow was designed to adapt seamlessly to the customer's existing structure, requiring minimal adjustments.

With the implementation of G-Flow, maintenance and intervention fees are virtually eliminated, allowing predictive maintenance to be scheduled every 2 to 3 years.

Request Contact

Old Pulley-Belt System

High maintenance rates and unplanned downtime.

Automatic Lubrication

Reduces the need for frequent maintenance.

Online Vibration and Temperature Monitoring

Enables early fault detection and continuous monitoring of equipment operating conditions.

Hoisting System

Allows easier access for maintenance.

Gear Motor

More reliable transmission system. Eliminates belt tension adjustments.

New Structure

More robust and does not require field welding.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.