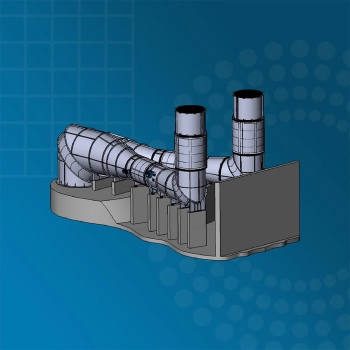

Secondary Fans for Underground Mining

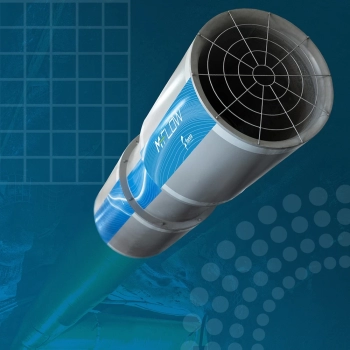

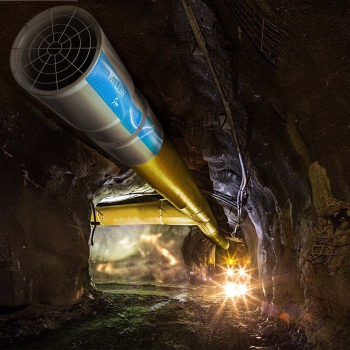

M-Flow

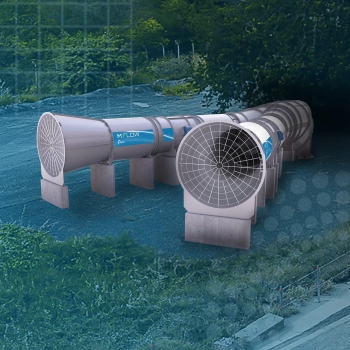

M-Flow secondary fans are designed for secondary ventilation in underground mines, supplying fresh air to working faces through ducts that prevent contamination with used air.

Compact and highly robust, they operate under high-pressure conditions with low noise and long service life, maintaining ventilation efficiency and stability even in challenging environments.

The evolution of the M-Flow line brought new versions and structural improvements that result in greater reliability and performance.

Request Contact

|  |  |  |  |  | ||

Model | Diameter | Airflow (cfm) | Static Pressure (inH2O) | Rotation - rpm* | Maximum installed power (kW) | ||

Minimum | Maximum | Minimum | Maximum | ||||

M-FLOW 08 | 33in | 15.000 | 42.000 | 4,01 | 22,08 | 3600 | 3000 | 93 |

M-FLOW 10 | 39in | 21.000 | 63.500 | 4,01 | 26,10 | 3600 | 3000 | 149 |

M-FLOW 12 | 47in | 32.000 | 106.000 | 2,00 | 16,06 | 1800 | 1500 | 186 |

M-FLOW 14 | 55in | 55.000 | 201.000 | 2,00 | 22,08 | 1800 | 1500 | 373 |

The values shown are examples and for guidance only.

Contact us for more technical information by clicking hereKey features include reinforced housing, blades with three-times higher edge resistance, optimized rotors, and reinforced protection screens, ensuring resistance to impacts and vibrations.

The improved cooling system guarantees extended motor life, while the flange mounting design for models up to 1400 mm allows the use of higher-power motors in compact structures.

Versions for operations above 1500 meters are also available, maintaining consistent performance and reliability.

The WEGScan Bluetooth monitoring system, with extended autonomy and rechargeable battery, provides real-time tracking of temperature and vibration, supporting predictive maintenance and enhancing operational safety.

With these advancements, M-Flow auxiliary fans ensure efficiency, strength, and reliability, delivering a constant flow of clean air to underground workplaces.

Silent Attenuator

The model offers low noise levels due to the density and composition of the materials.

Increased Plate Thickness

Provides greater stability and higher impact resistance.

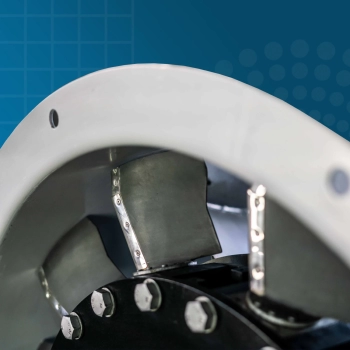

Leading Edge

Leading edge with 3x higher strength.

Motor Shroud

Motor shroud design makes the fan more aerodynamic.

Aerodynamic Stators

Stator design with aerodynamic profile.

Automatic Lubrication

Reduces maintenance needs and extends fan lifespan.

New Rotor Assembly

Greater precision in blade-to-housing clearance, with increased robustness.

Motor Cooling

Enhanced motor cooling system.

Lifting System

Simplified lifting system.

Monitoring System

Bluetooth monitoring with longer durability and modular battery replacement system.

Modified Spinner

Redesigned spinner for improved aerodynamic performance.

Reinforced Protection Screens

Protection screen redesigned for greater strength.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.