Primary Ventilation Projects for Underground Mines

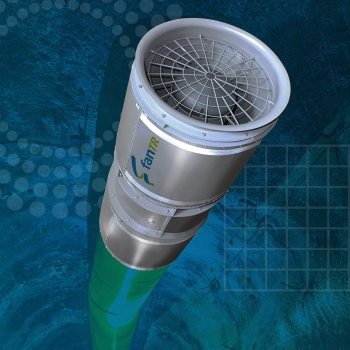

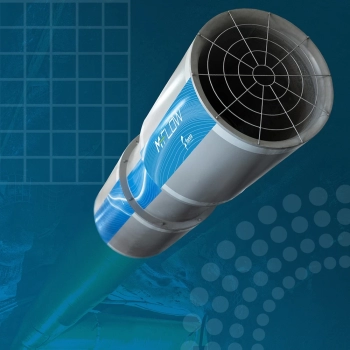

In primary ventilation projects for underground mines, FanTR adopts a comprehensive and customized approach, ensuring that each system is precisely designed to meet the specific requirements of every operation.

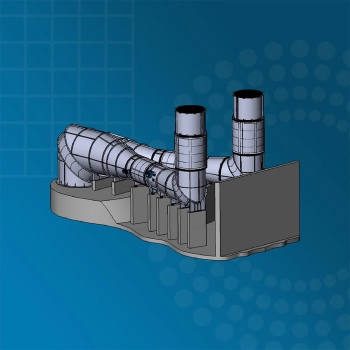

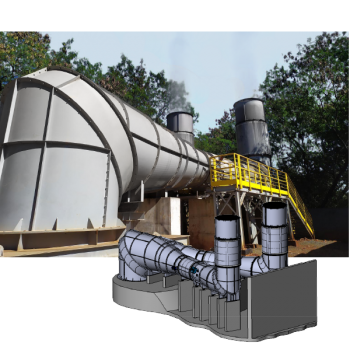

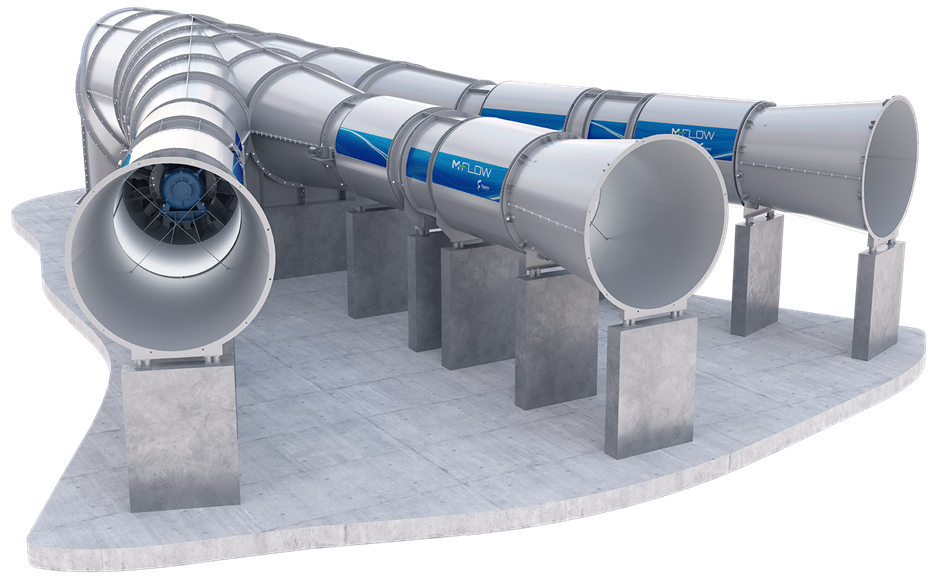

When supplying a ventilation system, it is essential to integrate all components — primary and auxiliary fans, ducts, attenuators, bends, and control devices — while considering the topographical conditions, space constraints, mine layout, and the required pressure and airflow parameters of each site.

Close collaboration between FanTR’s engineering team and the client’s technical staff is fundamental to this process. This partnership allows for a detailed understanding of the underground environment and ensures that the system is fully adapted to the real ventilation, safety, and energy-efficiency needs of the installation.

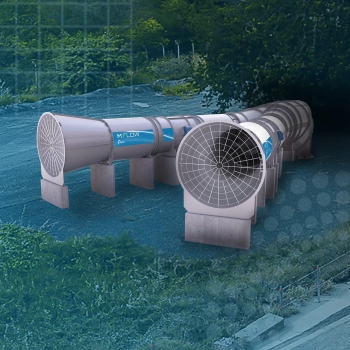

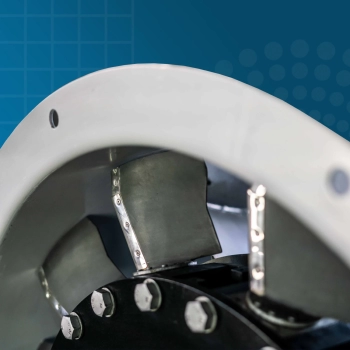

Request ContactFanTR stands out by employing advanced design and simulation tools such as CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis), enabling accurate prediction of airflow behavior and structural loads.

This engineering approach guarantees maximum aerodynamic performance, low energy consumption, reduced noise levels, and high operational reliability, even under the most demanding conditions.

By combining cutting-edge engineering, proprietary technology, and international expertise, FanTR delivers complete primary ventilation solutions that ensure the continuous circulation of clean air, effective control of gases and dust, and improved safety and comfort for workers — essential factors for productivity and sustainability in underground mining operations.

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.