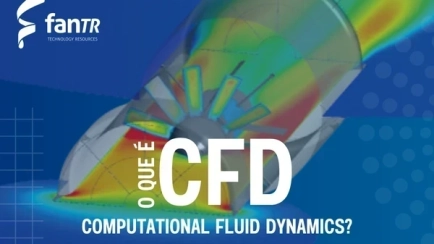

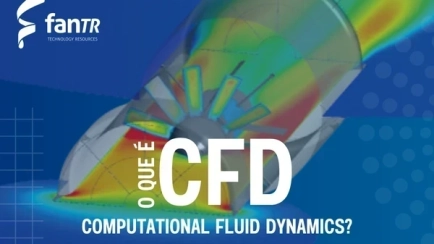

What is CFD (Computational Fluid Dynamics)?

CFD (Computational Fluid Dynamics) is a methodology used to calculate fluid flow in several applications. Through this, it is possible to obtain different types of results, such as velocity, pressure, and temperature of a fluid flow.

CFD is based on the finite volume numerical method that can solve a set of differential equations that govern the flow of a Newtonian fluid, known as Navier-Stokes equations. This methodology encompasses three main areas of knowledge: Computing, Fluid Mechanics, and Numerical Calculation of Differential Equations.

Application of CFD in Engineering

Most engineering problems that are of interest to the industry involve the calculation of complex flows, such as turbulent flows involving thermal exchanges, flows with supersonic velocity regimes, two-phase flows with chemical reactions, and generation and propagation of acoustic waves, among others.

Each type of flow presents its particularities and challenges for CFD modeling and, in some cases, the results can be obtained after hours of simulation, while in others it may take days, months, or even years. However, the simulation time depends on the numerical approach used, the level of accuracy required for the results, and the available computational processing capacity.

Key Characteristics of CFD

Nowadays, most companies that use CFD as a product development tool opt for commercial software. The main advantage of these softwares is the availability of a wide library of numerical methods and turbulence models, expanding the number of flow types that can be simulated by the user.

However, the disadvantage is that they can calculate a result that is not coherent with reality if the user does not use a numerical approach appropriate for the type of flow being calculated.

For this reason, the engineer's experience in CFD, together with a complete experimental validation, is fundamental for the CFD to be used to its maximum potential, providing reliable and important results for strategic decision-making during the product development process.

What are the applications of CFD at FanTR?

The use of CFD is fundamental for FanTR during the development process of its axial fans, as it allows for precise aerodynamic calculations. All products developed by the company are optimized with the help of CFD and validated through experimental tests.

After the 3D modeling of the fan's geometry, it is possible to calculate the airflow inside it, identify sources of efficiency loss and correct the problem by creating a more appropriate geometry.

In addition to the study of the fan itself, in some specific cases, it is necessary to use the CFD to calculate the flow in the ventilation system where the fan will be installed. Usually, the flow in the ventilation system is calculated upstream or downstream of the fan when there is a potential problem that needs to be carefully checked by engineering. These problems can include obstacles that can disturb the inlet flow and impair the fan's operation, or even obstacles in the outlet that generate additional pressure drop to the system, something that may not have been foreseen by the customer.

We can offer personalized customer support using CFD. Occasionally, unforeseen events happen and the equipment may be exposed to adverse operating conditions, different from those originally envisaged. In these situations, we can help the customer by performing simulations of its operation in virtual and controlled environments. In this way, it is possible to advise the customer on the best measures to be taken to minimize the problem.

FanTR also stands out for its experimental labs and test stations, which provide accurate results. It is important to mention that FanTR has an extensive library of experimental results, built over the years, which is essential to validate the CFD models applied to fans used in different markets and operating ranges. This ensures great assertiveness in the decisions made based on the results obtained by the CFD.

How important is the use of CFD for FanTR?

CFD plays a key role in reducing new product development time at FanTR, thus increasing competitiveness in the ventilator market.

Using CFD makes it possible to bring innovations to market more quickly, rather than following a long program of experimental tests. This is because it is possible to simulate and compare the efficiency of different geometries and choose the best option, thus reducing the number of experimental tests and consequently the cost associated with product development.

Furthermore, the use of CFD allows FanTR to study and visualize important details of the flow of the fan that are hardly captured in experiments, but which are fundamental for the development of new technologies that contribute to the increase of energy efficiency and reduction of noise emission.

Among the numerous advantages of using the CFD tool, it is important to emphasize that the CFD does not replace the actual tests that validate the ventilator's performance. Even with the aid of the tool, it is necessary to carry out experimental tests to ensure the reliability of the results and the safety of the product.

Share your questions and ideas with us by contacting us below.