Products

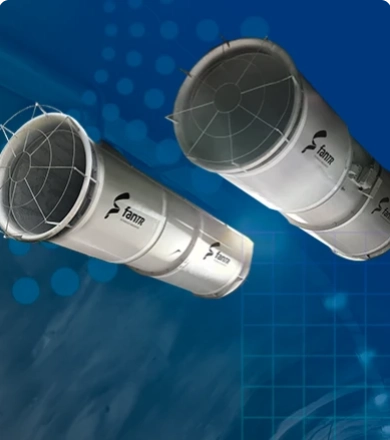

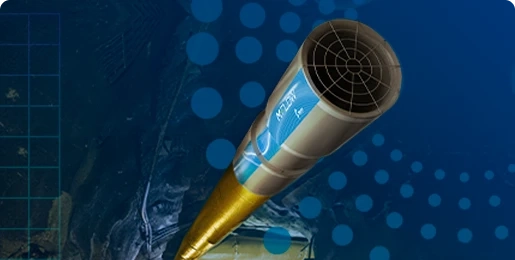

FanTR Products

Filter by application:

Contact us to discuss a FanTR solution

Let us know what you need and we will respond as soon as possible.